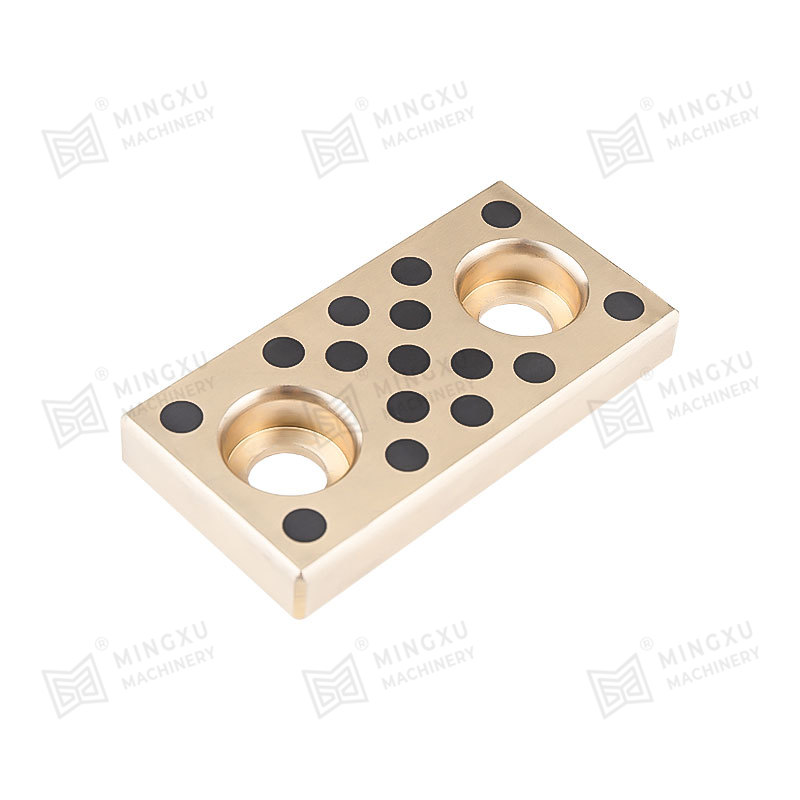

MXB-JFBB Zelfsmerend lager met hoge temperatuurbestendigheid

Cat:Zelfsmerend lager

Het zelfsmerende MXB-JFBB-lager is een schouderlager met grafietinleg op de flens, ontworpen om zelfsmerende eigenschappen te bieden. Het is gemaak...

Zie de detailsAdvancements in solid lubricant materials are critical for enhancing the performance of solid-lubricating bearings in high-speed applications. High-speed environments pose challenges like increased frictional heat, wear, and reduced efficiency, requiring innovative solutions. Here are some key advancements:

Nanotechnology in Solid Lubricants

Nanocomposites: Combining traditional solid lubricants like graphite or molybdenum disulfide (MoS₂) with nanoparticles (e.g., graphene, carbon nanotubes) can enhance their thermal stability and wear resistance.

Benefits for Bearings: Solid-lubricating bearings with nanocomposite coatings can operate more effectively at high speeds due to lower friction and better heat dissipation.

High-Temperature Solid Lubricants

Ceramic-Based Lubricants: Advanced ceramics, such as silicon nitride or boron nitride, offer excellent high-temperature stability and low friction, making them ideal for high-speed applications.

Benefits for Bearings: Bearings made with or coated in these materials maintain lubrication properties even at the elevated temperatures generated by high-speed operation.

Metal Matrix Composites (MMC)

Lubricant Integration: Embedding solid lubricants (e.g., MoS₂ or graphite) directly into a metal matrix provides a strong, durable bearing material with self-lubricating properties.

Benefits for Bearings: This design improves wear resistance and ensures consistent lubrication even under high rotational speeds and loads.

Polymer Innovations

Enhanced Polytetrafluoroethylene (PTFE): Modified PTFE with additives like glass fibers or carbon increases durability and reduces wear at high speeds.

Polymer Composites: New polymer blends infused with solid lubricants are being developed to combine flexibility, low friction, and high-speed performance.

Benefits for Bearings: These materials make solid-lubricating bearings lighter, quieter, and capable of withstanding the stresses of rapid motion.

Adaptive Solid Lubricants

Phase-Changing Materials: Some modern solid lubricants can change their structure at high temperatures or pressures to provide optimal lubrication dynamically.

Benefits for Bearings: These adaptive properties ensure that solid-lubricating bearings perform well across a range of operating speeds and conditions.

Surface Engineering and Coatings

Diamond-Like Carbon (DLC) Coatings: DLC coatings on solid-lubricating bearings reduce wear and friction significantly, even at very high speeds.

Advanced Plasma Spraying: This technique can deposit uniform, high-performance solid lubricant coatings on bearing surfaces, enhancing their durability and speed capabilities.

Hybrid Lubrication Approaches

Combination Systems: Bearings with both solid lubricant layers and microchannels for emergency liquid lubrication are being developed for ultra-high-speed applications.

Benefits for Bearings: This hybrid approach provides the stability of solid lubrication with added lubrication for extreme conditions.

Future Potential

The development of these materials is paving the way for solid-lubricating bearings that can:

Handle higher speeds without increasing maintenance requirements.

Operate in extreme conditions like aerospace, where high rotation rates and temperature variations are common.

Provide consistent performance and long lifespan, even under dynamic stresses.

Het zelfsmerende MXB-JFBB-lager is een schouderlager met grafietinleg op de flens, ontworpen om zelfsmerende eigenschappen te bieden. Het is gemaak...

Zie de details

MXB-JDB zelfsmerende lagers, ook bekend als met grafiet ingelegde bronzen bussen, zijn nieuwe smerende lagers die zowel de kenmerken van metalen la...

Zie de details

MXB-JDBS op brons gebaseerd massief ingelegd zelfsmerend sferisch lager is een sferisch glijlager. Het glijdende contactoppervlak is een bolvormig ...

Zie de details

MXB-JDBUF zelfsmerende gietbronzen lagers combineren de voordelen van zelfsmerend en flensontwerp. De grondstoffen zijn gemaakt van hoogwaardige ge...

Zie de details

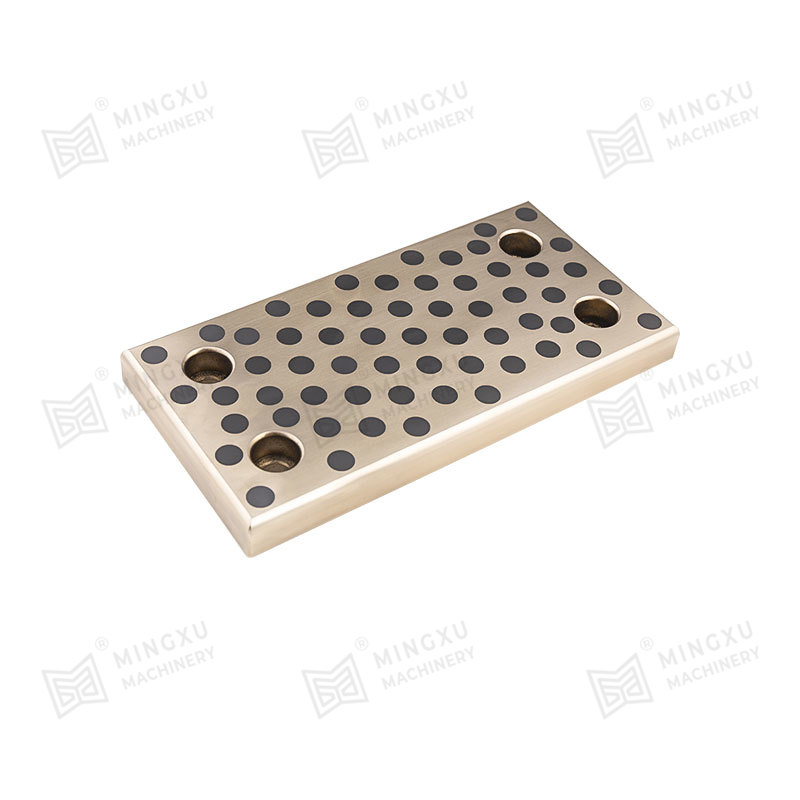

MXB-JOLP zelfsmerende slijtplaten hebben goede zelfsmerende eigenschappen en vereisen geen externe smering. Dit product heeft een goed draagvermoge...

Zie de details

MPW VDI3357 standaard slijtplaat wordt gemaakt door speciaal vast smeermiddel in de juiste positie te plaatsen. Het metalen basismateriaal onderste...

Zie de details

Normaal gesproken wordt de duwplaat ondersteund door vier resetstangen. Als de duwplaat echter groot en zwaar is, buigen de resetstaven vanwege de ...

Zie de details

SF-1D hydraulic bearing is a new type of material designed based on SF-1P and combining the working principle of oil cylinder and shock absorber. It i...

Zie de details

SF-1S stainless steel corrosion-resistant bearing is a very effective corrosion-resistant material that is formed by rolling with stainless steel as t...

Zie de details

SF-1P reciprocating bearing is a novel formula product designed based on the structure of SF-1X material and according to the special common condition...

Zie de details

Neem contact met ons op